IMTS22: Kaiser Manufacturing’s Kaizen Shadow Foam inlays are customized on a shop-to-shop basis in order to best capture the tool storage needs of each individual company. #imts

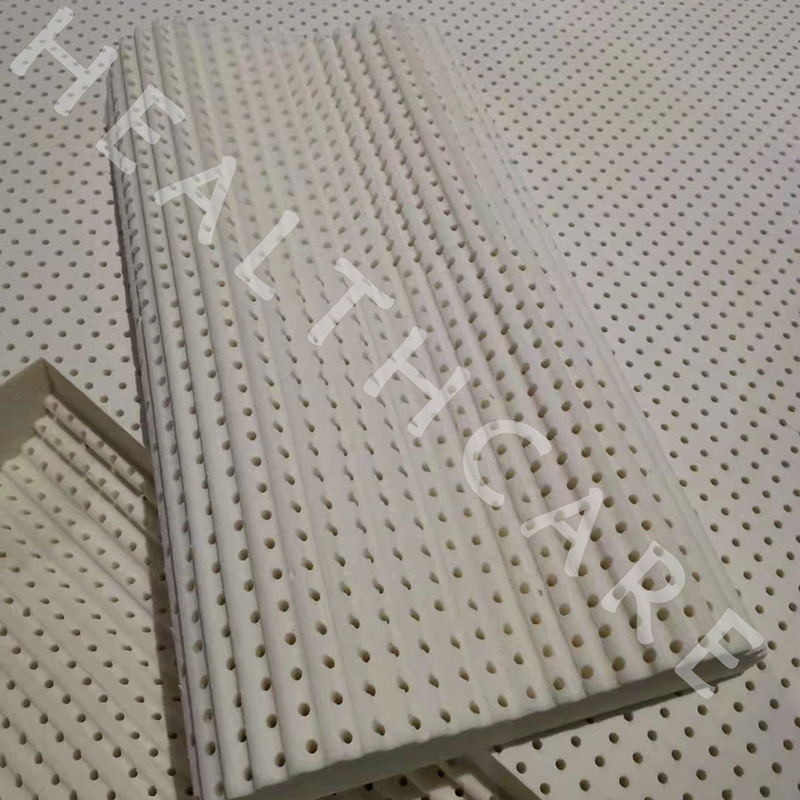

A start-up company near Chicago designs and fabricates custom tool foam inlays for toolboxes, workstations, travel cases and reusable packaging. Kaiser Manufacturing says its process fills the need for a custom solution that is superior to hand-cut tool foam in both function and appearance. Cnc Dual Blade Foam Cutting Machine

The problem Kaiser seeks to solve for its customers is how to create a custom foam inlay for their unique mix of tools and accessories. No two shops have the same set up, so Kaiser introduced portable 3D scanners to quickly capture the layout for a full drawer of tools.

The LED scanner can capture a part profile or layout of 24 x 48 inches or more with an accuracy of 0.02 inch. The 3D files are converted to CAD, and the design is machined in two-color foam to nest each tool and fit the specific workstation, case or drawer.

The 3D scanning kits, complete with a video tutorial, are available on a rental basis or as a turnkey service. This makes it convenient for customers to scan tool layouts in their own shop, helping eliminate the potential to ship tools out, download or license software, or purchase any equipment. According to Kaiser, it also saves engineering time compared to designing tool trays in house, and the finished product is more professional than hand-cut foam.

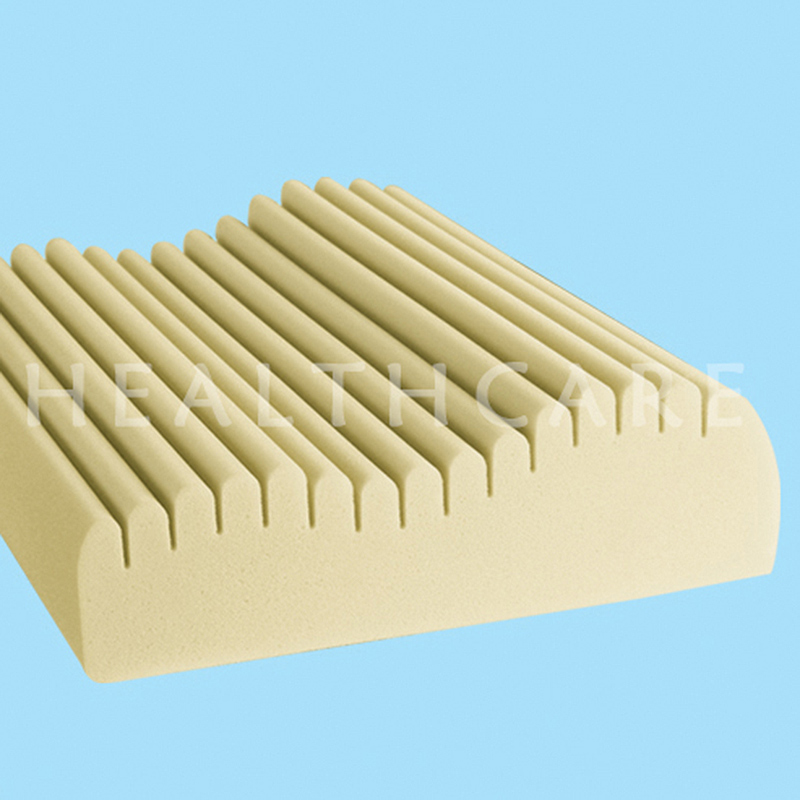

The two-color material, called Kaizen Shadow Foam, is a durable and closed-cell polyethylene that is dust-free, resistant to oils and solvents and can be cleaned. Kaiser says the foam’s highest popularity is in lean manufacturing environments, 5S initiatives and FOD prevention.

Read: A New Spin on CNC Machining Face Grooves

When expensive cutting tools or collets or holders shift around in drawers, they can be easily damaged. With companies investing a considerable amount of money in top quality tooling, gauges and other equipment, Kaiser seeks to help protect this investment by providing proper storage to reduce both damage and waste.

Kaiser adds there are other benefits for this type of tool organization. It was designed to save time so an operator can reach a tool without having to search, enable smooth shift changes where everything is in its place, and aid with contrasting colors in creating a visual workspace and highlight missing tools to improve asset retention and reduces spending on replacement tools.

The International Manufacturing Technology Show runs September 12 - 17, 2022 at McCormick Place in Chicago. Register for IMTS today to start planning your show.

Kaiser Manufacturing will be exhibiting new technology at IMTS 2022 in Chicago this September.

Plan to meet up with their team or get registered here!

Autodesk software supports practical applications in the machine shop as well as imaginative creations in the inventor’s studio.

Weiler’s V 110 four-way precision lathe introduces features new to the U.S.

Sponge Cutter The realm of medical manufacturing includes precision cleaning, exacting tolerances, additive manufacturing, ins and outs of FDA clearance and more. Anyone in the industry can learn more and keep up to date with latest in medical manufacturing at IMTS.